HP Pop rivets

Length- ---

Material grade - --

Drilling Capacity - ---

Material - Stainless Steel

Usage/Application- Industrial

Color- --

Minimum Order Quantity: -- Packaging Type: Bag

Blind rivets, also commonly referred to as POP Rivets, are mainly used in applications where there is no access to the rear (blind side) of the joint. Rivets have a two-piece construction; one is called the rivet body, shell, or hat, and another is called the stem or mandrel. Both the hat and mandrel are pre-assembled and ready to use. Rivets are installed by using a riveting tool to draw the mandrel, which causes the body to deform and clamp down on the joint. Upon reaching the designed clamping force, the mandrel snaps and is discarded. A benefit of blind rivets is that they are not material-specific, meaning they can combine two different material types together the same way.

To use a blind rivet, a hole is drilled, then the rivet is seated inside of the hole. Then a tool pulls the mandrel against the hat of the rivet. The back of the mandrel either has a bulge on the end or is connected to the hat in some way, which makes the edges of the hat expand down towards the material. Once this expansion reaches the material and builds pressure, a designed fault in the mandrel reaches its peak force capacity and snaps, leaving a properly installed rivet.

One of the biggest benefits of rivets is that there is no way to over- or under-torque a rivet. If the appropriate diameter and grip range are chosen, the rivet will install perfectly every time.

Applications

- Sheet Metal Joining: Used to join thin metal sheets together in automotive and aerospace industries.

- Assembly Lines: Common in manufacturing assembly lines for fast, efficient fastening.

- Home and Industrial Repairs: Used for repairing metal objects or structures.

- Signage and Displays: Fastens panels for signs, displays, and advertisements.

Process

- Drill a Hole: Drill a hole into the materials you wish to join.

- Insert Rivet: Place the pop rivet into the hole, ensuring the rivet’s mandrel is aligned with the hole.

- Use Rivet Gun: Use a rivet gun to pull the mandrel, expanding the rivet to secure the materials.

- Break the Mandrel: Once fully installed, the mandrel will break off, leaving a tight and permanent hold.

HP Top Rivet Rate List 1-4-22

| SIZE | BOX PACKING | Quantity in one bag |

|---|---|---|

| 3.2x6mm (1/8 X 1/4) | 15000 | 35000 |

| 3.2x10mm (1/8 X 3/8) | 15000 | 30000 |

| 3.2x13mm (1/8 X 1/2) | 15000 | 30000 |

| 3.2x16mm (1/8 X 5/8) | 15000 | 25000 |

| 3.2x19mm (1/8 X 3/4) | 6000 | 25000 |

| 3.9x6mm (5/32 X 1/4) | 6000 | 25000 |

| 3.9x10mm (5/32 X 3/8) | 6000 | 25000 |

| 3.9x13mm (5/32 X 1/2) | 6000 | 25000 |

| 3.9x16mm (5/32 X 5/8) | 6000 | 20000 |

| 3.9x19mm (5/32 X 3/4) | 6000 | 20000 |

| 3.9x25mm (5/32 X 1") | 6000 | 15000 |

| 4.8x10mm (3/16 X 3/8) | 6000 | 20000 |

| 4.8x13mm (3/16 X 1/2) | 6000 | 20000 |

| 4.8x16mm (3/16 X 5/8) | 6000 | 15000 |

| 4.8x19mm (3/16 X 3/4) | 6000 | 15000 |

| 4.8x25mm (3/16 X 1") | 4000 | 10000 |

| 4.8x32mm (3/16 X 1 1/4") | 4000 | 10000 |

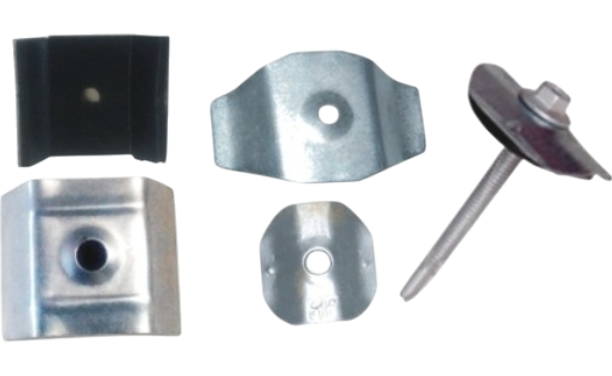

Explore Similar Products

Dry Wall Screw

HP Self Drilling screws

HP Pop rivets

HP socket