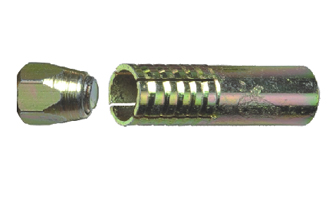

Sleeve and Taper Nut

Plating - Zinc

Material grade - 4.6

Diameter - 6, 8, 10, 12, 16

Material - Mild Steel

Usage/Application- Concrete, Masonry, and Solid Brick

Heat Treatment - Not Required

Minimum Order Quantity: 1 peice Packaging Type: Boxes

FMAN Sleeve and Taper Nut Anchors are crafted for high-strength and reliable anchoring solutions in heavy-duty construction projects. Designed with a durable sleeve and a precision taper nut, these anchors expand upon installation, offering superior holding power and load-bearing capacity. They are ideal for applications requiring secure fastening to concrete, brick, or stone surfaces.

These anchors provide a strong and stable connection for materials like masonry and solid brick. The sleeve and taper nut design ensures secure installation, distributing loads evenly and minimizing stress on the base material.

Applications

- Suitable for high-load applications in concrete, brick, and stone.

- Through-fix installation with sleeve expansion.

- Ensures stable and durable fastening by uniformly distributing load.

Process

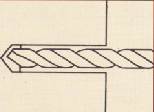

- Drill a hole corresponding to the diameter of the anchor.

- Insert the anchor into the hole.

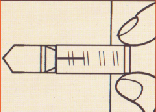

- Tighten the external hex nut or bolt to expand the sleeve on taper nut and secure the anchor within the material.

- Verify the anchor is firmly in place for optimal load support.

Technical Chart

| 6 mm Rod Dia | 8 mm Rod Dia | 10 mm Rod Dia | |

|---|---|---|---|

| Tension Load | KN | KN | KN |

| 4.0 | 6.10 | 9.7 |

- Battens

- Fire protection boards

- Air Condition Duct works

- Metal profiles

- Ventilation systems

- Fixing of doors & windows frames

- Wire & nonious hangers

- Substructures made of wood & metal

- Overhead cable trays

- Chains

- Ceilings

- Fire partitions

- Punched tapes

- Metal clamps

- Plasterboards

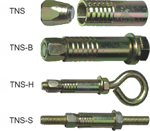

FI-TNS

6 x 11 x 3

8 x 12.5 x 35

10 x 16 x 42

12 x 19 x 60

16 x 25 x 75

12 x 100

FI-TNS-B

6 x 40

8 x 50

10 x 60

10 x 75

12 x 75

FI-TNSH

6

8

10

12

16

FI-TNSS

6

8

10

12

16